In the high-stakes world of aerospace engineering, every gram of weight and every fraction of a degree in temperature can make or break a design. Finite Element Analysis (FEA) has become one of the industry’s most important tools, allowing engineers to simulate, refine, and validate designs long before a single part is built. Today’s aerospace companies rely on a mix of powerful commercial suites, specialized solvers, and open-source tools to get the job done. From aircraft manufacturers like Boeing and Airbus to space players such as SpaceX and NASA, FEA is part of nearly every stage of development — from early concept models to flight certification.

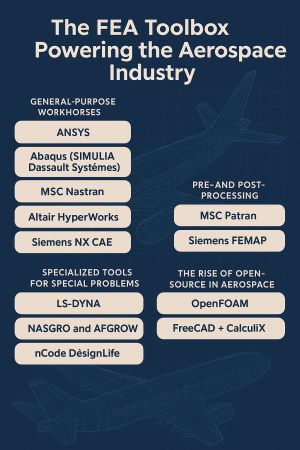

General-Purpose Workhorses

For most structural and thermal simulations, engineers turn to full-featured commercial packages:

ANSYS is a favorite for its multiphysics capabilities, letting teams analyze fluid-structure interactions and thermal-stress coupling in complex systems like jet engines.

Abaqus (SIMULIA, Dassault Systèmes) shines in non-linear problems and composite material modeling, critical for spacecraft heat shields or satellite bus structures.

MSC Nastran, a NASA original, remains the industry benchmark for structural analysis, trusted for everything from wing deflection to satellite panel vibration.

Altair HyperWorks brings best-in-class meshing with HyperMesh and optimization capabilities with OptiStruct.

Siemens NX CAE integrates CAD, CAM, and CAE under one roof, letting teams design and simulate in the same environment — a major productivity boost.

Pre- and Post-Processing: The Unsung Heroes

Preparing a model for analysis is just as critical as solving it. Tools like MSC Patran and Siemens FEMAP are mainstays for setting up meshes, defining loads, and interpreting results, particularly when working alongside Nastran.

Specialized Tools for Special Problems

When projects demand extreme accuracy, engineers turn to niche software:

LS-DYNA for crash simulations, impact events, and “blade-out” scenarios.

NASGRO and AFGROW for fracture mechanics and fatigue crack growth, helping ensure structural safety over long service lives.

nCode DesignLife for predicting how components behave under countless stress cycles.

These programs help aerospace companies meet rigorous safety standards while minimizing costly physical testing.

The Rise of Open-Source in Aerospace

Even in an industry dominated by commercial software, open-source tools are gaining ground. OpenFOAM provides a powerful platform for CFD studies, and FreeCAD paired with CalculiX is finding a place in research labs and startups looking to experiment without heavy licensing costs.

FEA has evolved from a niche tool to an indispensable part of aerospace development. As aircraft become lighter, engines more efficient, and spacecraft more ambitious, the role of simulation will only grow. For engineers, mastering these tools isn’t just helpful — it’s essential.

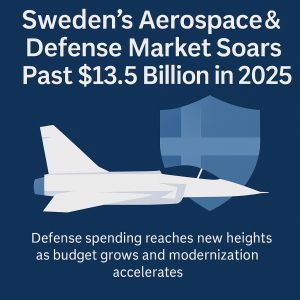

Sweden’s defense industry is entering its busiest decade in recent memory. In 2025, the country’s defense spending reached $13.5 billion, a 14.1% increase over 2024, marking the first time Sweden has exceeded NATO’s 2% GDP guideline — coming in at 2.3% of GDP.

This is more than just a budget figure. It signals a clear shift in Sweden’s role on the global stage. The increase follows Sweden’s formal accession to NATO earlier this year, a decision widely seen as a response to Russia’s ongoing war in Ukraine.

Modernization and Industry Impact

The bulk of this new funding is being directed toward modernization programs. Saab, Sweden’s largest defense company, is ramping up production of the Gripen E fighter jet for both domestic and export customers. Its 2024 first-quarter report showed 91% of total sales were defense-related, with strong performance in its Aeronautics and Surveillance divisions.

The Swedish Armed Forces have also announced procurement plans for new Patriot air defense systems, expanded radar and early-warning capabilities, and investments in cyber defense infrastructure. The navy is upgrading its submarine fleet, and the army is accelerating purchases of artillery and armored vehicles.

Looking Ahead

The growth isn’t stopping in 2025. The Swedish government’s 2026 budget bill, presented in September, adds another $2.87 billion (SEK 26.6 billion) to defense — an 18% jump — pushing spending to 2.8% of GDP. If approved, this would represent one of the largest year-over-year increases in Swedish defense history.

Market analysts expect a 6.7% compound annual growth rate (CAGR) for Sweden’s defense market from 2026 to 2030, fueled by multi-year NATO capability targets and a long pipeline of modernization projects.

Opportunities for Industry Players

The spending surge is a boon for aerospace and defense contractors. Saab is already hiring additional engineers for Gripen and radar programs. International firms like Raytheon, BAE Systems, and Thales are competing for contracts in missile defense, communications, and surveillance technology. Maintenance and support providers are also expected to benefit as the Swedish military expands its equipment inventory.

Why It Matters

For Sweden, this isn’t just about budgets — it’s about readiness. The country is building a modern, NATO-integrated defense force. For industry professionals and suppliers, this means years of project opportunities, from advanced fighter programs to cybersecurity solutions.

What is CATIA 3DX?

CATIA 3DX is the modern version of CATIA (Computer Aided Three-dimensional Interactive Application), now part of Dassault Systèmes’ 3DEXPERIENCE platform. It’s not just software — it’s a connected, cloud-enabled environment where designers, engineers, and manufacturers can work together on the same product in real time, no matter where they are in the world.

For companies in automotive and aerospace, this means faster innovation, fewer errors, and smoother collaboration between teams.

CATIA V5 vs. CATIA 3DX — The Big Shift

| Feature | CATIA V5 (Traditional) | CATIA 3DX (Modern) |

|---|---|---|

| Where it runs | Installed on a single computer, saving files locally. | Runs on a shared platform — can be cloud-based — so everyone sees the same data. |

| How data is handled | Engineers save separate files, which can get out of sync. | A single, central database keeps everything updated automatically. |

| Teamwork | Teams email files or use shared drives to collaborate. | Teams work on the same model at the same time, even from different continents. |

| Ease of use | A classic but older interface. | Modern, web-like interface that feels more intuitive. |

| Scalability | Requires heavy IT setup and maintenance. | Scales easily for growing teams with subscription-based access. |

In short, CATIA 3DX moves design from a file-based world to a collaborative, connected world.

Real-World Impact in Automotive

In the fast-paced automotive industry, speed and precision are critical. CATIA 3DX helps automakers:

Develop new models faster: Teams can design, test, and refine vehicle components in the same digital space, cutting down prototype costs.

Collaborate across suppliers: Whether a supplier is in Germany, Japan, or the U.S., they can work on the same virtual car in real time, avoiding delays and misunderstandings.

Support electric and autonomous vehicle innovation: CATIA 3DX integrates mechanical, electrical, and software systems, making it easier to design complex EV powertrains and ADAS (advanced driver-assistance systems).

For example, an electric car manufacturer can simulate battery placement, crash performance, and aerodynamics — all virtually — before ever building a physical prototype.

Real-World Impact in Aerospace

In aerospace, safety, complexity, and global collaboration make CATIA 3DX a game-changer. It enables:

Digital twin development: Engineers can create a “virtual twin” of an aircraft, testing everything from aerodynamics to wiring systems digitally before physical production.

Global collaboration: Aerospace programs involve hundreds of suppliers worldwide. CATIA 3DX keeps everyone connected to the same source of truth, preventing costly rework.

Regulatory compliance: The platform tracks design history and changes automatically, making audits and certification easier.

Imagine designing a new jetliner: thousands of parts, miles of wiring, and strict safety requirements. CATIA 3DX helps keep all that complexity organized, ensuring the final aircraft is safe and built right the first time.

Why It Matters

CATIA 3DX isn’t just for engineers — it connects the entire product lifecycle: from concept sketches to factory floor planning. The result is:

Faster time to market

Fewer mistakes and rework

Better collaboration between designers, suppliers, and manufacturers

Reduced costs thanks to virtual testing and fewer physical prototypes

For industries like automotive and aerospace, where innovation cycles are getting shorter and competition is fierce, CATIA 3DX provides a significant competitive advantage.